Electronics ProductsThermo-setting Electrical Insulation Film SJ41

"SJ41" is an thermo-setting electrical insulation adhesive film and also has suitable adhesion for various materials such as metals and resins, etc...

The conventional liquid type adhesive material has high adhesion strength and high heat resistance. However, its workability is an issue in comparison with adhesive tape.

TOMOEGAWA's adhesive film is molded to sheet form with thermo-setting liquid glue by our proprietary developed process. This unique adhesive film maintains high adhesive strength and high heat resistance with improved workability.

The application of adhesion to small parts and any fragile parts has increased with the continuing trend of down-sizing and weight-saving for industrial products. Since our adhesive film can fully cover all necessary surrounding area , it strongly adheres even with small or low strength parts.

An example of customer's inquiry.

Feature 1The adhesive film achieves a merit of liquid type adhesive and adhesive tape.

The conventional liquid type adhesive material has high adhesive strength and high heat resistance. However, its workability is an issue in comparison with adhesive tape.

TOMOEGAWA's adhesive film is molded to sheet form with thermo-setting liquid glue by our proprietary developed process. This unique adhesive film maintains high adhesive strength and high heat resistance with improved workability. TOMOEGAWA's adhesive film DOES NOT require refrigeration.

| Merit | Demerit | |

|---|---|---|

| Thermo-setting adhesive film SJ41 |

|

|

| Liquid type adhesive material |

|

|

| Pressure sensitive adhesive tape |

|

|

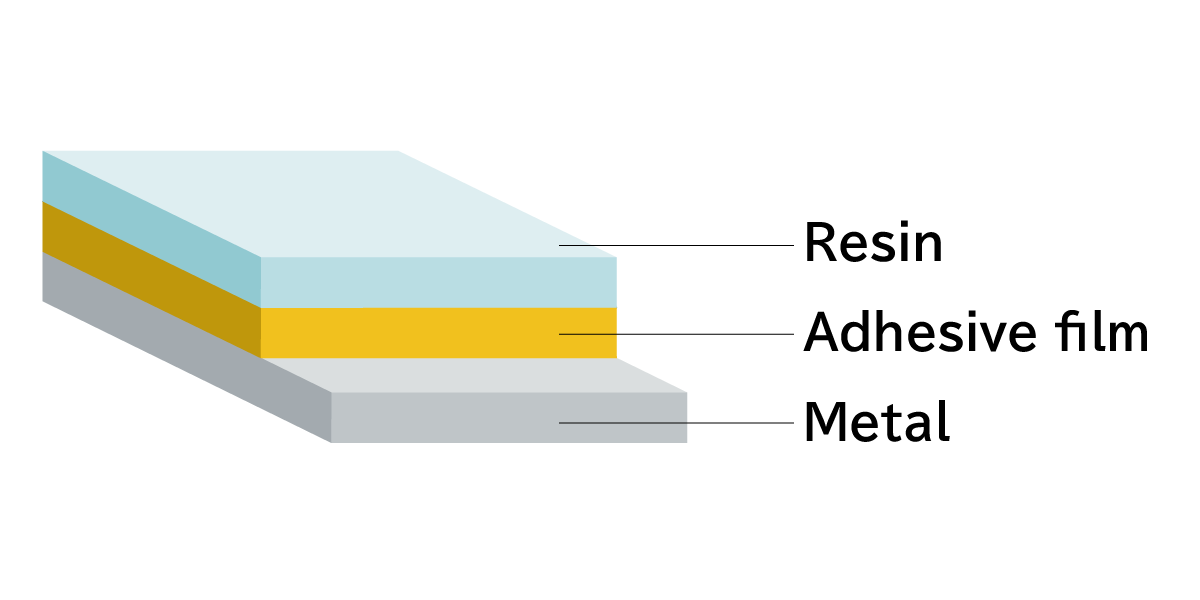

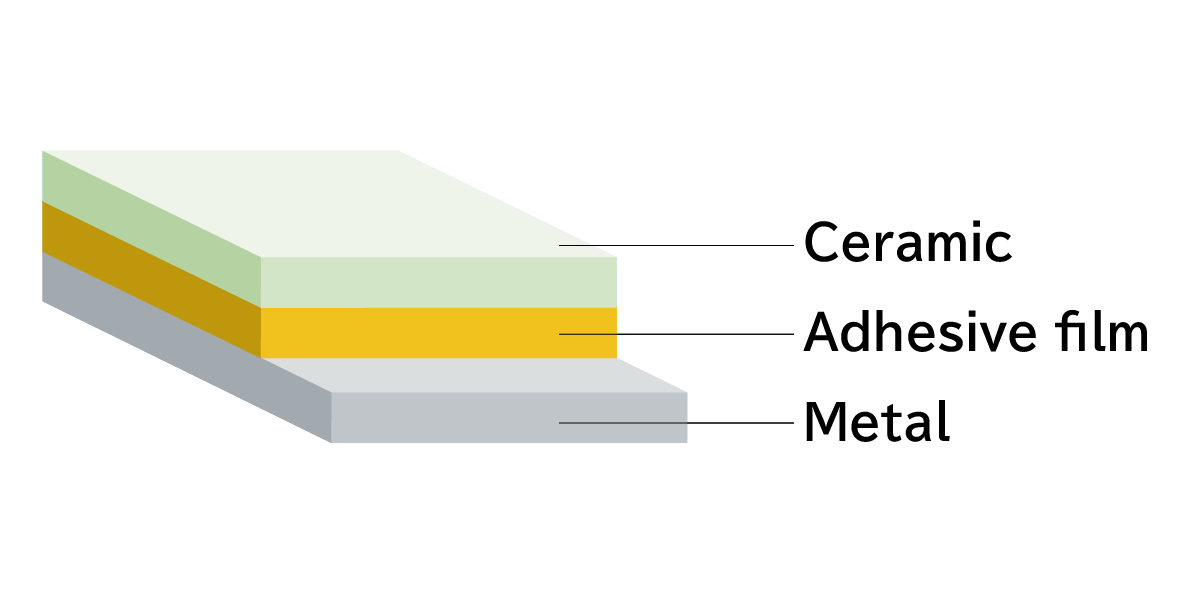

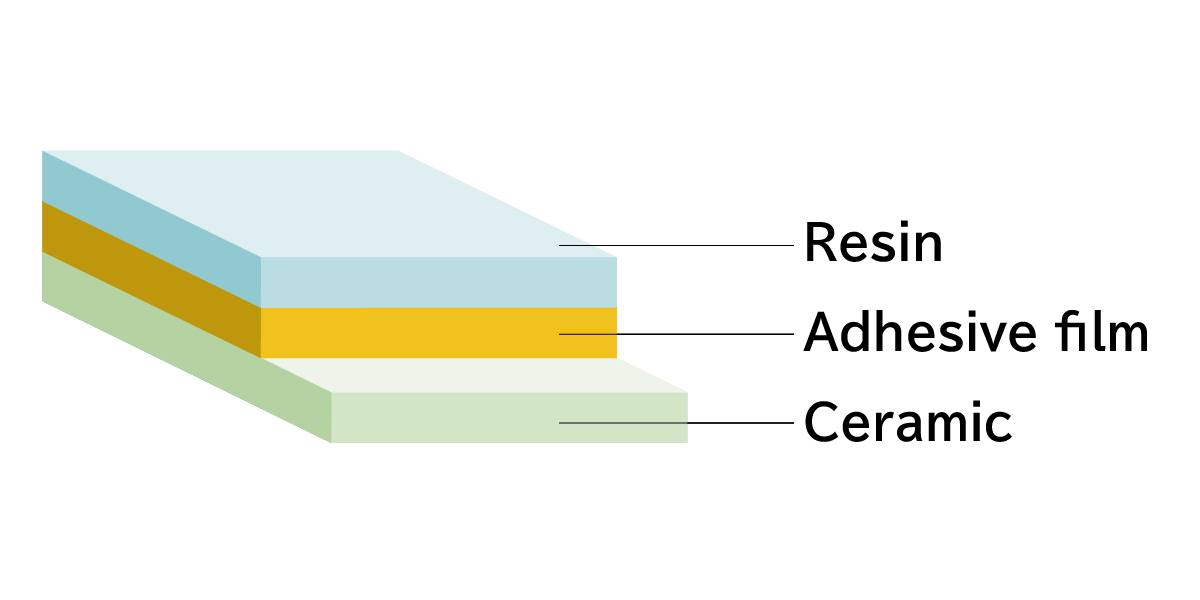

Feature 2It is possible to adhere to metals and resins, etc.

It is possible to adhere to the following materials.

- Metals: SUS, Copper, Aluminum, Nickel, etc.

- Resins: Polyimide, Glass epoxy, FRP, etc.

- Others: Ceramic such as Alumina, Glass, etc.

The film strongly adheres to various materials like the below.

Technical data

| Characteristic item | Specification | Remarks |

|---|---|---|

| Thickness (μm) | 20 | |

| Adhesion strength (N/cm) | 17 | Adherend: SUS304 |

| Breakdown voltage (KV/mm) | 230 | |

| Tackiness under room temp. | No | |

| Curing condition | 150℃~200℃ 0.5~1hr or longer |

|

| Application temp | 100~120℃ | |

| Storage | Room temperature |

※The data are references, not guaranteed values.

Application

- Electronic materials

The film has good result for years because of its high reliability. - Automotive parts

To keep high adhesion strength and contribute to weight-saving.

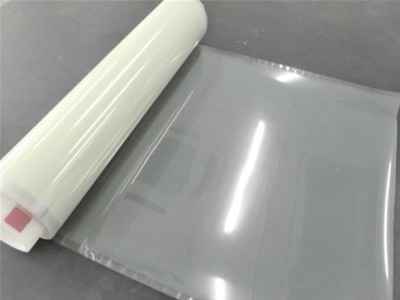

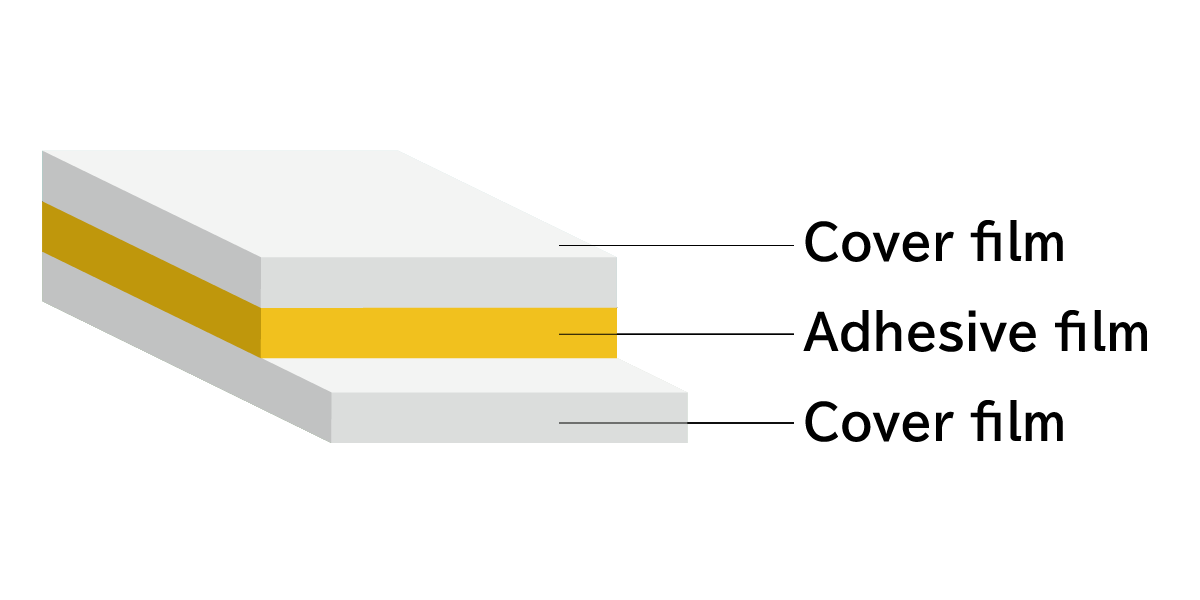

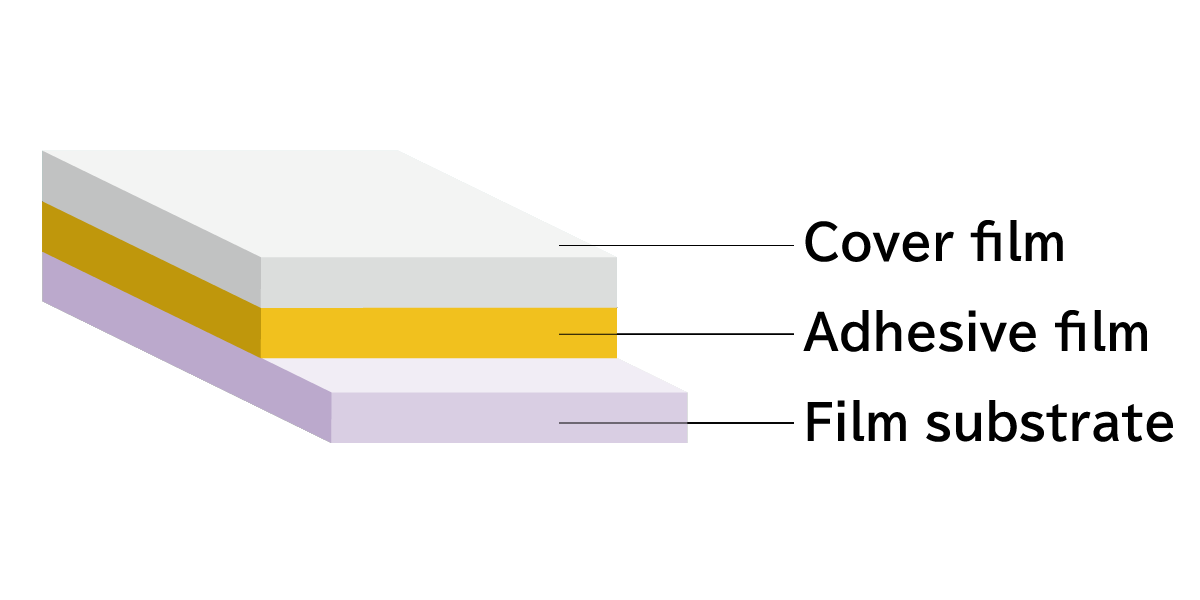

Layer Structure

※Thickness of adhesive layer and cover film is adjustable.