Heat/Electricity/Electromagnetic WavesThermal Conductive Insulation Adhesive Sheet iCas KR

Pressure-free in curing process-thermal conductive adhesive-thermal conductive adhesive iCas KR

Thermal conductive insulation adhesive sheet iCas KR is a thermosetting adhesive sheet that combines heat dissipation, insulation, and high temperature heat resistance.

It has excellent resistance to high temperatures, so it is suitable as a TIM (thermal interface material) for power devices such as automotive equipment and various equipment parts.

Feature 1Excellent processability with high heat dissipation characteristics without pressure during curing process

Thermal conductive adhesive sheets are generally cured under pressure, but iCas KR has high heat dissipation properties even when curing without pressure.

In addition, since it is a sheet type, there is no pumping out or liquid dripping compared to heat dissipation grease and liquid type heat conduction adhesive, and the thickness uniformity after lamination is good.

Feature 2Both thermal conductivity and durability (insulating and heat resistance to high temperatures)

iCas KR contains inorganic fillers with excellent thermal conductivity in polyimide and epoxy resin.

Therefore, while possessing high heat dissipation, it has excellent insulation and durability.

In addition, by softening the adhesive layer during temporary bonding, it follows the uneven surfaces of the adhered surface and reduces thermal resistance.

Since there is almost no deterioration in characteristics after durability testing, it can be applied to applications used in harsh environments such as automotive and industrial equipment.

Technical Data

| Characteristic item | Specification | Measurement method |

|---|---|---|

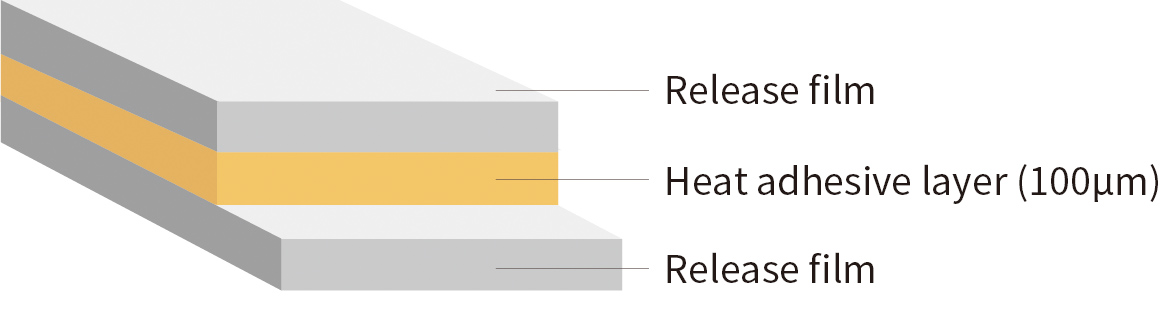

| Standard adhesive thickness | 100 μm | |

| Thermal conductivity | 3.2 W/m・K | Non-stationary method |

| Dielectric breakdown voltage (AC) | 65 kV/mm | 25°C/55%RH・JIS compliant・Short-time boost test |

| Heat-resistant insulation | No drop in breakdown voltage after high temperature Initial 85 kV/mm (DC) → 87 kV/mm after 150°C-500h |

|

| Shear strength | 2.6Mpa | 25°C-55%RH・Adhesive aluminum plate |

| Peeling strength | 8.1N/cm | 25°C-55%RH・Electrolytic copper foil・Vertical peeling |

* The Technical data are calculated values, not guaranteed values.

Application

Suitable for bonding and heat protection of the following products:

- Various equipment, electronic components

- Power device modules for automotive and industrial equipment

- High Brightness LED Board

Moreover, it can be applied as a substitute for heat dissipation grease and liquid thermal conductive adhesive.

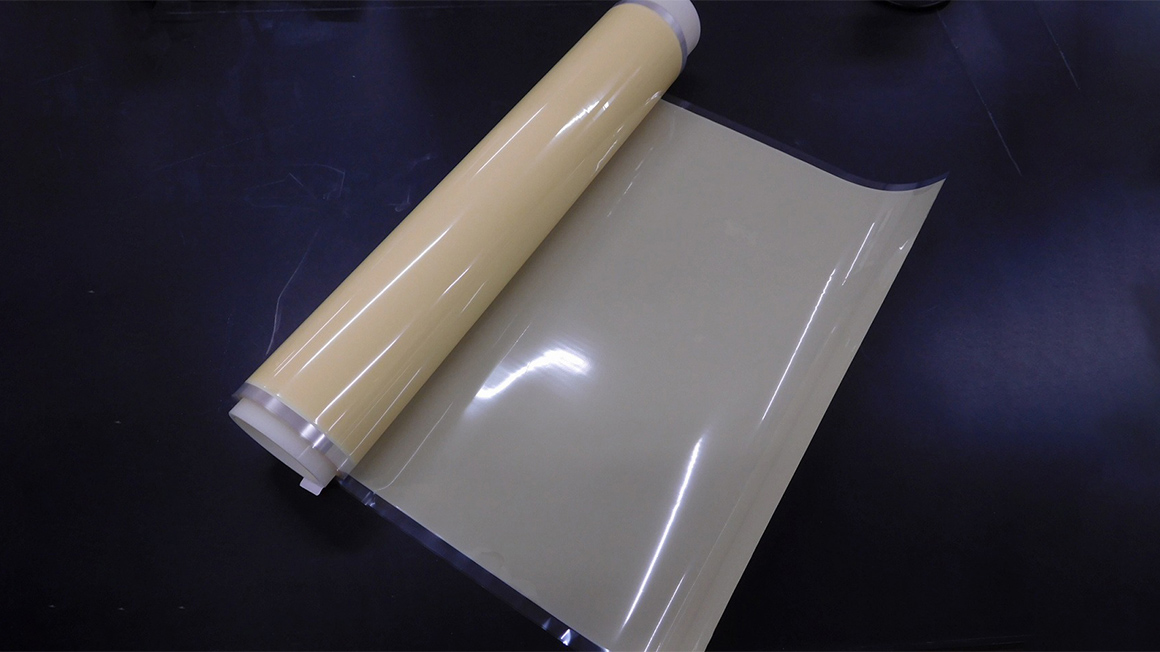

Layer Structure