New ProductsCellulose Fiber Compounded GREEN CHIP CMF

Biomass compound resin containing wood-derived cellulose fiber, contributing to sustainability

The convenience of plastic

and the eco-friendliness of biomass

TOMOEGAWA's Approach to a Circular Economy

Reducing Environmental Impact through Carbon Neutrality

TOMOEGAWA was established in 1914 as a paper manufacturer.

Having always used wood-derived materials,

it was only natural that we would ask ourselves how we could make

more environmentally friendly products. Our concern for the environment led us to create a technology

for homogeneously dispersing cellulose fiber in petroleum-derived resin.

Forests absorb CO2 and release O2 as part of their growth process. If properly managed and cared for, they become a sustainable resource.

Our GREEN CHIP CMF contains 55% wood-derived cellulose fiber, significantly reducing the use of petroleum-derived plastics.

Added Value from Our Cellulose Fiber Formula

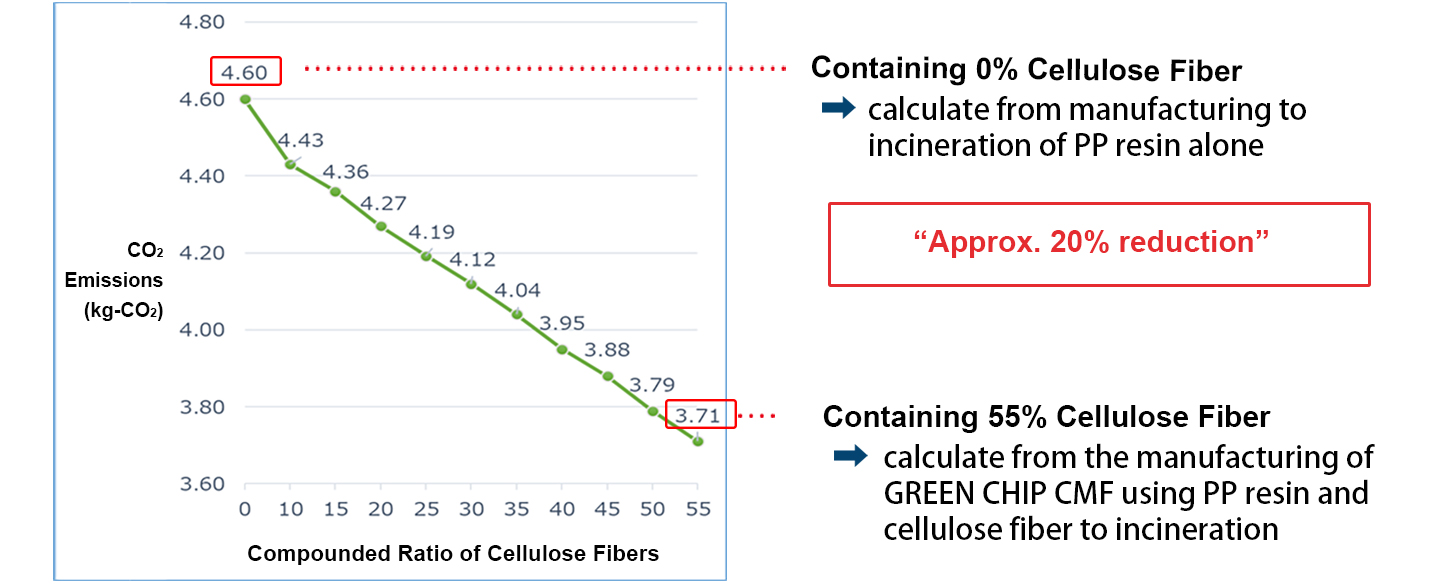

Reduced CO2 emissions throughout, from manufacturing to incineration (compared to petroleum-derived plastics)

When using GREEN CHIP CMF, which contains 55% cellulose fiber, the amount of total CO2 emissions, from manufacturing to incineration,

can potentially be reduced by approximately 20%*1 compared to petroleum-derived resins.

(*1) By our own calculations based on the Ministry of the Environment's "Guidelines for the Utilization and Application of Cellulose Nanofiber Towards the Decarbonization and Achievement of a Circular Economy" of March 2021

Click Here for More Information

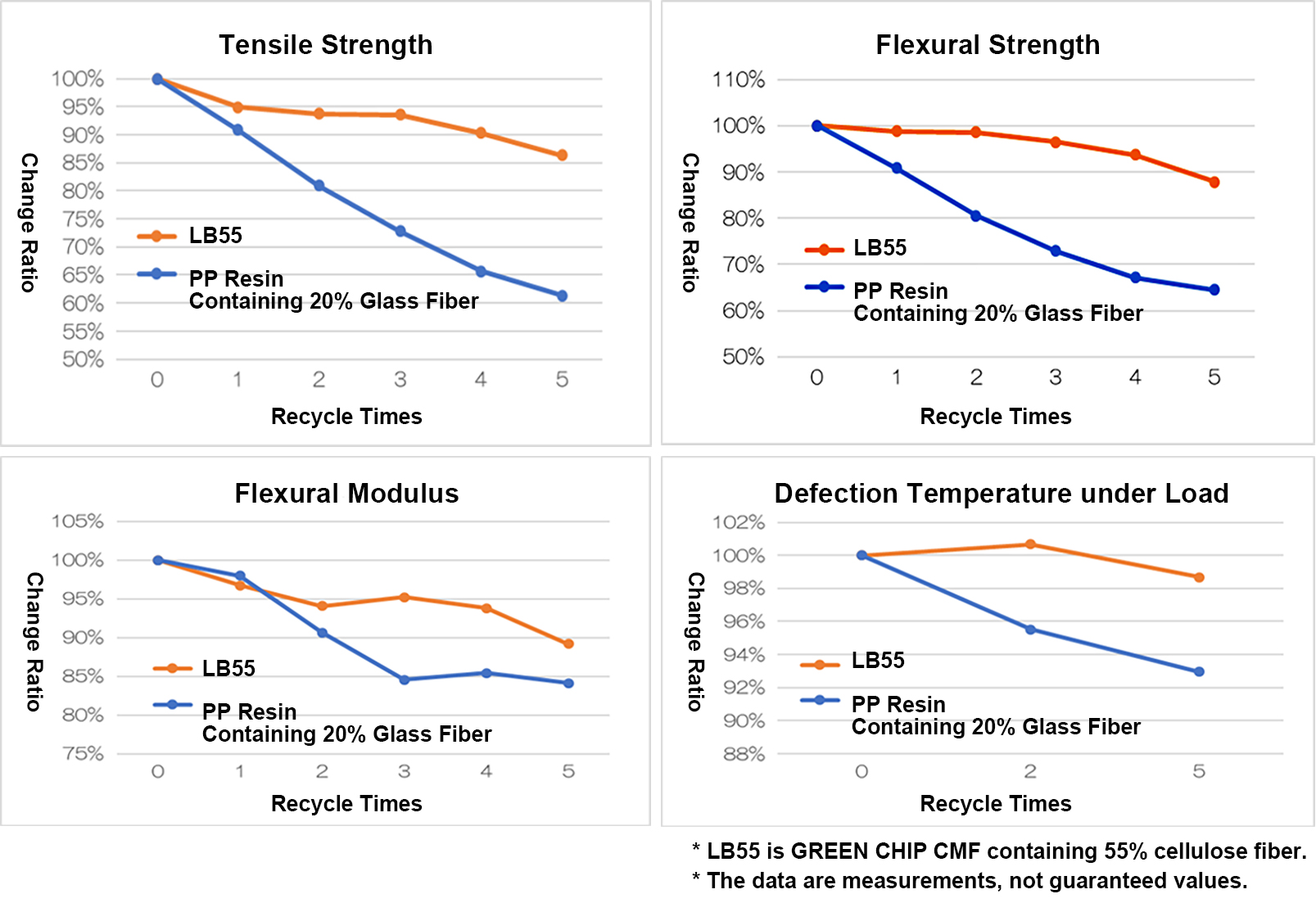

Building a Circular Economy through Recycling

GREEN CHIP CMF is a material that can be recycled through material recycling.

As part of our in-house testing, we evaluated test pieces that had been crushed and molded five times. Test results showed that the attenuation (damping) rate was superior to that of glass fiber compounds.*2

(*2) Based on our in-house evaluation process

Click Here for More Information

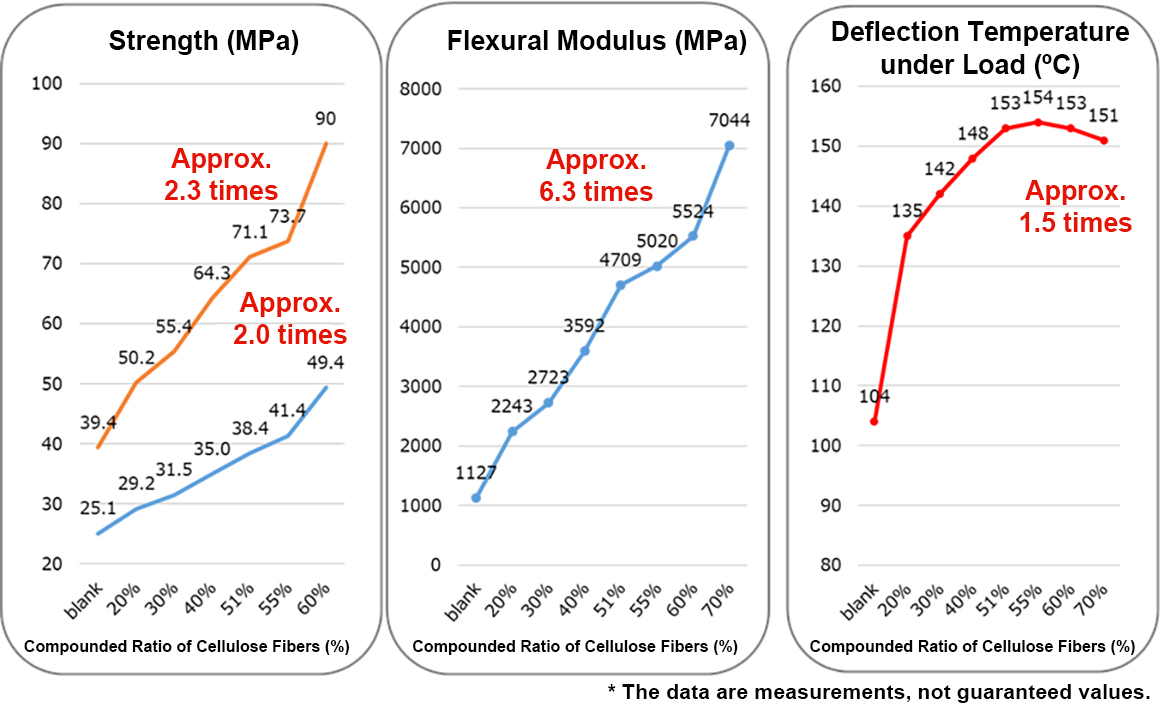

Additional Role of Reinforcing Agent

Cellulose fiber also acts as a reinforcing material.

Tensile strength, flexural strength, flexural modulus and heat resistance (load deflection temperature) are improved compared with unreinforced polypropylene resin (PP resin).

This makes it possible to make molded products thinner and, therefore, lighter, too.

Click Here for More Information

High MFR(Melt Flow Rate) for Easy Molding

No need to replace currently used molds

While containing 55% cellulose fiber, GREEN CHIP CMF has the same level of fluidity as polypropylene resin, which makes it highly moldable.

Therefore, it can be introduced as an alternative to petroleum-derived plastics using existing molds.

It also shows little shrinkage during molding and excellent dimensional stability.

Designability that Spurs Creativity

Boasting a high degree of designability that allows the creation of unique textures depending on molding conditions,

and being compatible with color processing, GREEN CHIP CMF makes it possible to create patterns and textures

that are not possible with conventional polypropylene resins.

Moreover, while it is generally difficult to print on olefin resins, GREEN CHIP CMF can be directly printed onto finished products.

- Flexible coloring and delicate hues

- Thin wall molding also possible

- Unique textures can be created on the surface of products depending on molding conditions

- Printing on the surface of molded products is also possible.

Safety and Environmental Certifications

- GREEN CHIP CMF has obtained the Biomass Mark in Japan and TUV AUSTRIA OK biobased certification in Europe.

- It complies with Specifications and Standards for Foods, Food Additives, etc. (Ministry of Health and Welfare Notification No. 370, 1959)

- It complies with Europe's COMMISSION REGULATION (EU) No. 10/2011 of 14 January on plastic materials and articles intended to come into contact with food.

*Please verify the compliance of each molded product individually.

Meeting the Following Customer Needs (Frequently Asked Questions)

Our technology improves the cellulose fiber dispersibility and the resin flowability, allowing for a higher cellulose fiber content and reducing the amount of petroleum-derived resin used.

It also boasts excellent injection moldability and high dispersibility of cellulose fibers, allowing for a higher compounding ratio.

Please contact us about compounding it with resins other than polypropylene.

Applications

【Transportation field】

Automobiles (interiors), aircraft (interiors), ships, etc.

【Home appliances field】

Smartphones and other electronic devices, large household electrical appliances, inspection and evaluation equipment, etc.

【Construction materials field】

Housing interiors, kitchens and bathrooms, plumbing, etc.

Actual Usage Examples

- Mawal Tableware by FP Chemical Industries Co., Ltd.

- "Nogakel" Tableware by FURUTA Kasei

- Mug Cups by Outdoor store SWEN (Encho Co., Ltd.)

- Carton (Cash Trays) by various financial institutions

- Chopsticks by MASUDA PLASTIC & CHEMICALS. INC.

- Others: Construction materials / Decking materials (Extrusion molded products)

- GREEN CHIP CMF is the product jointly developed with FP Chemical Industries Co., Ltd.