Display ProductsWavelength Absorption and Color Compensation Adhesives for Optics

Supports various needs such as seamless and UV protection.

It is a color correction adhesive that controls the transmittance of ultraviolet light (UV) and visible light. With our unique “dispersion technology” and “coating technology, we have achieved a low haze and uniform optical surface. Fine adjustment of color tone and transmittance is possible according to your request.

It is recognized for its high durability and appearance quality, and has been adopted for various purposes such as color ajustment of the display and UV protection.

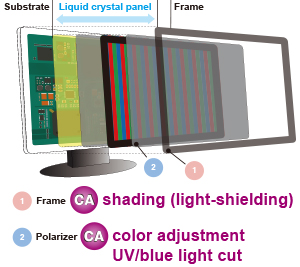

Product example 1Color adhesives that can generate seamless effects for flat panel display application

We can control the transmission depends on your requirement.

Our color adhesives has been well accepted for a wide range of applications including automotive for long. Thanks to both the advanced dispersion and experienced coating technologies, we have turned our color adhesives into a stand-out solution with its color uniformity and low haze performance.

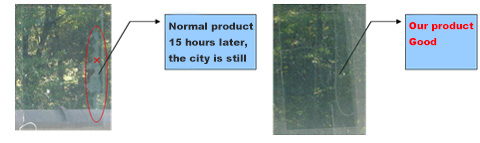

Product example 2UV cut adhesives.

It can cut long-wavelength side of UV. It's also possible to adjust Yellow-Color. Moreover, water paste type is available. It's applicable for window of automotive, building, etc.

Comparison of evaporativity

Data

| Characteristic items | Neutral gray | |||

|---|---|---|---|---|

| Characteristics | Contrast adjustments | Contrast adjustments | High black concentration | |

| Thickness [um] | 25 | 22 | 125 (Black PET) 25 (Black adhesives) |

|

| Adhesive strength [N/25mm] | 19 | 29 | 23 | |

| Transmittance rate [%] | 74 | 57 | 0 | |

| Haze [%] | 1.3 | 3.7 | - | |

| Wavelength selective absorption [nm] | Visible light area | Visible light area | Visible light area | |

| Durability | 80℃ x 1000hrs. | OK | OK | OK |

| 60℃90%RH x 1000hrs. | OK | OK | OK | |

| -40℃ x 1000hrs. | OK | OK | OK | |

| Recommended adherend | PET, glass, TAC | |||

| Characteristic items | UV-cut | Neon-cut | ||

|---|---|---|---|---|

| Characteristics | High durability | Workability (Drainability) |

Wavelength selective absorption | |

| Thickness [um] | 25~100 | 12 | 22 | |

| Adhesive strength [N/25mm] | 28 | 12 | 27 | |

| Transmittance rate [%] | 92 | 92 | 73 | |

| Haze [%] | 1 | 1 | 0.8 | |

| Wavelength selective absorption [nm] | ~ 410 | ~ 380 | ~ 600 ~ | |

| Durability | 80℃ x 1000hrs. | OK | OK | OK |

| 60℃90%RH x 1000hrs. | OK | OK | OK | |

| -40℃ x 1000hrs. | OK | OK | OK | |

| Recommended adherend | PET, glass, TAC | |||

Usages

- Color compensation for various displays such as LCD, OLED, mini LED, Micro LED, etc.

- Seamless for frame printing of display for home application and automotive.

- lamination for window material of automotive, building materials, etc.

etc...

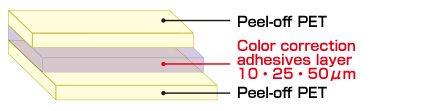

Structure

Related Products

Transparent adhesion for optics(TA-series)

Diffuse adhesive for optics(DA-series)